Automated-ready SPINx series and precision hotplates now shipping without lead times

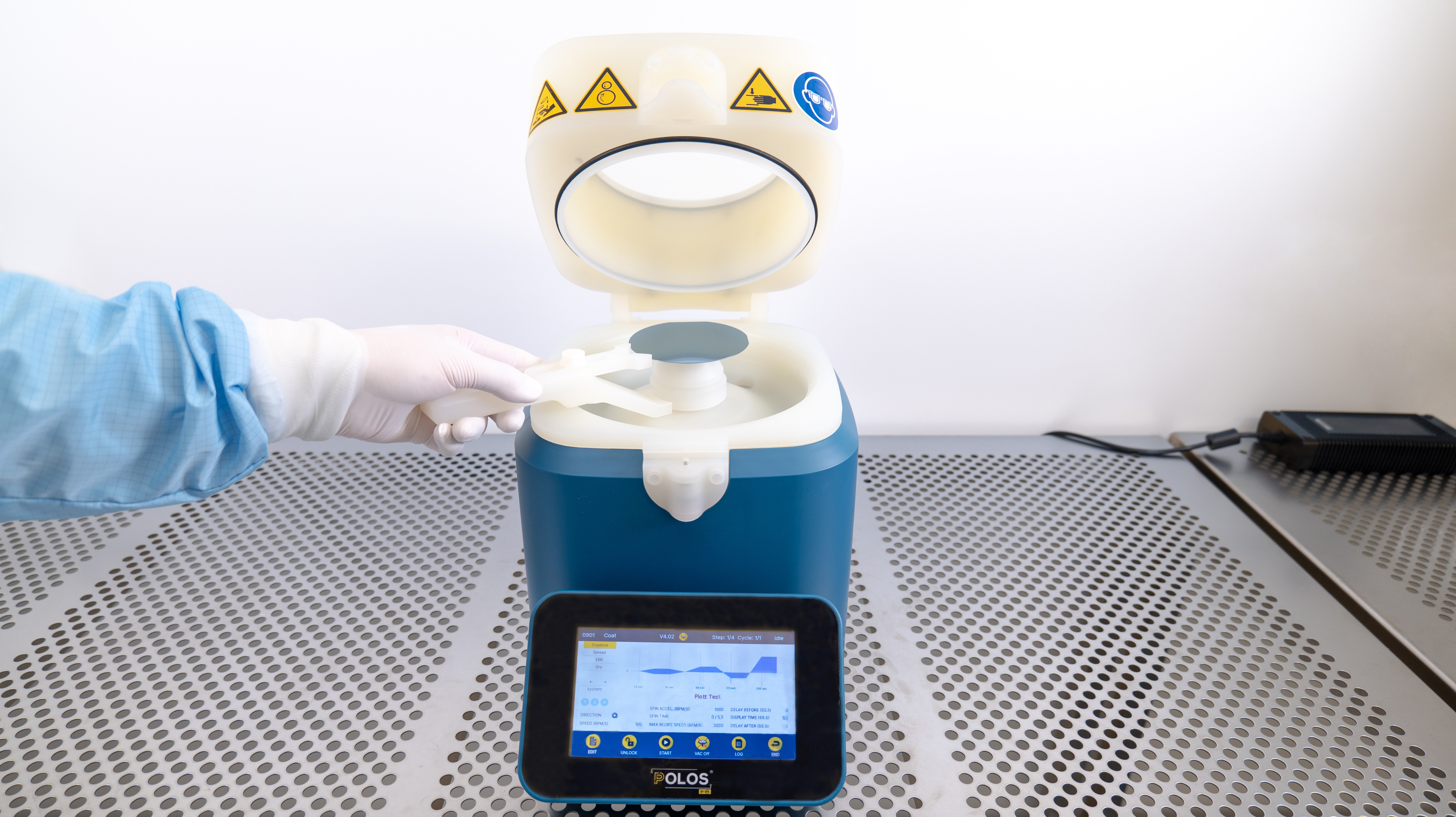

You can now order our new improved and innovative designed POLOS® SPIN150x model. The POLOS® SPIN150x offers precise, repeatable process control. It is made from natural polypropylene (NPP) or optionally available in chemically resistant PTFE. This new version of the well-proven model comes in a standard and an advanced version. It is ideal for processing a wide range of substrates with a diameter of up to 150 mm or square samples with dimensions 100 x 100 mm.For more information about our SPINx Series please visit: https://www.sps-international.com/webshop/photolithography/coating/

Putten, THE NETHERLANDS, Feb. 03, 2026 (GLOBE NEWSWIRE) — SPS-International, a specialized supplier of semiconductor equipment and cleanroom consumables, today announced the immediate availability from stock of its POLOS® SPINx spin processors and POLOS® hotplates. This inventory update allows research universities and semiconductor FABs to procure essential wet and thermal processing tools without standard manufacturing lead times.

POLOS® SPINx spin processor with touchscreen control and PTFE bowl

Automated-ready Spin Processing The POLOS® SPINx series is designed for high-precision coating and etching in R&D and low-volume manufacturing environments. Compatible with substrates from 150mm (6”) to 450mm (15”), the processors are available in Natural Polypropylene (NPP) or chemically resistant PTFE.

Key technical specifications include:

- Control: Indirect brushless drive reaching 12,000 RPM with programmable motor homing for robotic integration.

- Versatility: Clockwise/counterclockwise rotation and puddle mode capabilities.

- Design: Convertible from table-top to in-deck mounting, with Advanced models featuring auto-lid functionality and linear dispense arms.

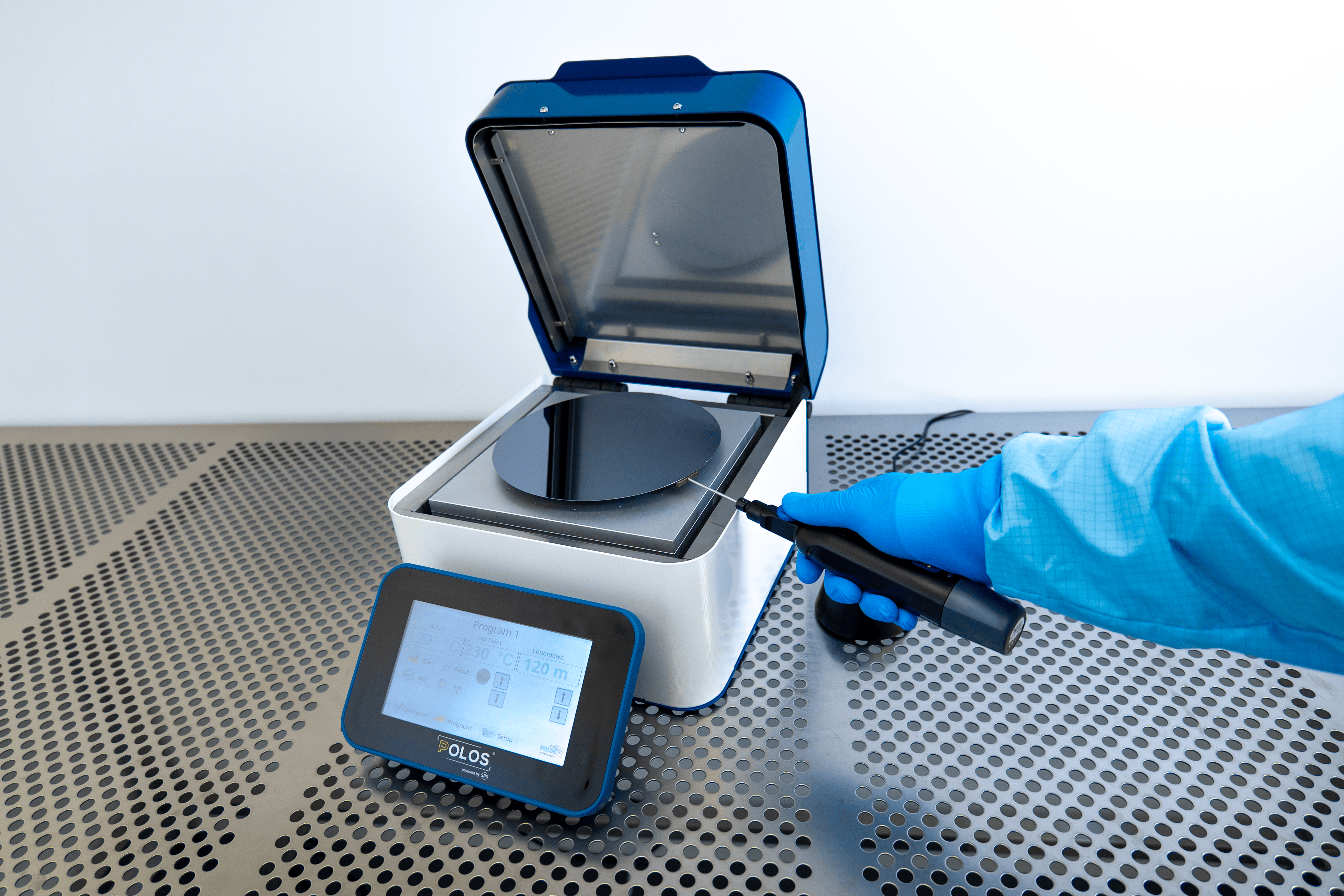

Precision Thermal Stability Complementing the wet processing line, the POLOS® Hotplate 200 and 350 systems are now available for immediate shipment. These units provide temperature control up to 230°C with a uniformity of ±1°C, critical for repeatable soft and hard bake processes. The advanced configurations include N2 connectors, vacuum bake, and proximity pins for contact-free heating, ensuring full cleanroom compliance.

Supporting Accessories To support these core tools, SPS-International has also stocked essential peripherals, including ESD-safe cordless vacuum wands (HEPA filtered) and high-temperature polyimide vacuum tips.

Comment on Availability “In the semiconductor R&D sector, project timelines are often dictated by equipment delivery schedules,” said Melissa Doppenberg, Marketing Specialist at SPS-International. “By keeping our core SPINx and Hotplate series in stock, we allow labs to deploy automated-ready, high-precision processes immediately.”

For technical specifications or to request a quote, visit sps-international.com.

About SPS-International

SPS-International is a leading supplier of wafer handling systems, cleanroom consumables, and semiconductor manufacturing equipment based in Putten, The Netherlands. The company serves a global client base of Fabs, research institutes, and universities.

POLOS® Hotplate with programmable temperature control up to 230°C

Press Inquiries

Melissa Doppenberg

SPS-International Marketing Department

+31 341 360 590

info [at] sps-international.com

Melissa.Doppenberg [at] sps-international.com

https://www.sps-international.com/

Midden Engweg 41

3882 TS Putten

Netherlands

A video accompanying this announcement is available here: https://youtube.com/watch?v=L2mfrB88gY4

Disclaimer: The above press release comes to you under an arrangement with GlobeNewswire. Mango Bunch takes no editorial responsibility for the same.

Disclaimer: The above press release comes to you under an arrangement with GlobeNewswire. Mango Bunch takes no editorial responsibility for the same.